Businesses relying on quick data access need robust network infrastructure to stay productive. High latency and slow speeds can hinder performance. Fiber optic cabling is a go-to solution for improved integration and efficiency.

Yet, when fiber optic networks falter, they morph into costly nuisances. Identifying and mitigating common failures are essential steps to keeping your operations running smoothly. What can cause your fiber optic to fail you? Let’s explore the main issues plaguing fiber optic systems and strategies to prevent them.

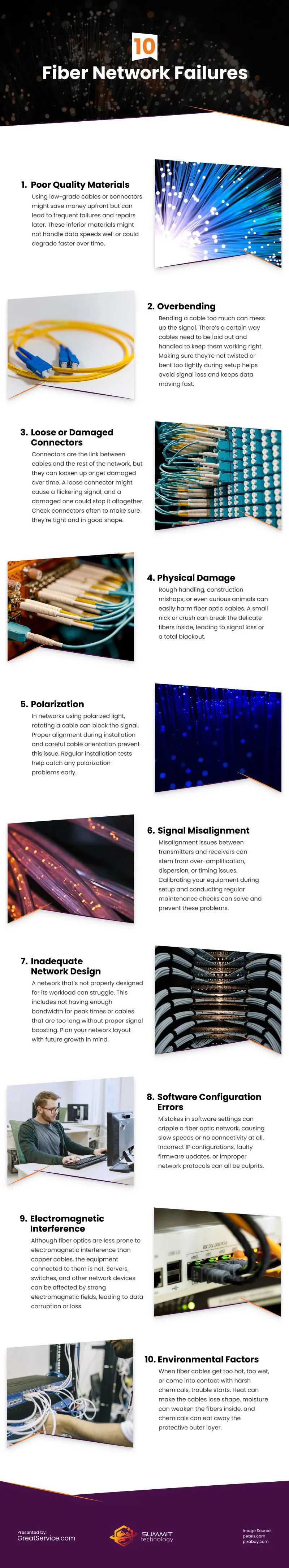

Common Causes of Fiber Network Failure

1. Poor Quality Materials

Using low-grade cables or connectors might save money upfront but can lead to frequent failures and repairs later. These inferior materials might not handle data speeds well or could degrade faster over time. Invest in high-quality components to ensure your network’s reliability and longevity.

2. Overbending

Bending a cable too much can mess up the signal. There’s a certain way cables need to be laid out and handled to keep them working right. Making sure they’re not twisted or bent too tightly during setup helps avoid signal loss and keeps data moving fast.

3. Loose or Damaged Connectors

Connectors are the link between cables and the rest of the network, but they can loosen up or get damaged over time. A loose connector might cause a flickering signal, and a damaged one could stop it altogether. Check connectors often to make sure they’re tight and in good shape.

4. Physical Damage

Rough handling, construction mishaps, or even curious animals can easily harm fiber optic cables. A small nick or crush can break the delicate fibers inside, leading to signal loss or a total blackout. Protect cables with sturdy conduits and keep them away from high-traffic areas.

5. Polarization

In networks using polarized light, rotating a cable can block the signal. Proper alignment during installation and careful cable orientation prevent this issue. Regular installation tests help catch any polarization problems early.

6. Signal Misalignment

Misalignment issues between transmitters and receivers can stem from over-amplification, dispersion, or timing issues. Calibrating your equipment during setup and conducting regular maintenance checks can solve and prevent these problems.

7. Inadequate Network Design

A network that’s not properly designed for its workload can struggle. This includes not having enough bandwidth for peak times or cables that are too long without proper signal boosting. Plan your network layout with future growth in mind and use repeaters or amplifiers where necessary to prevent these issues.

8. Software Configuration Errors

Mistakes in software settings can cripple a fiber optic network, causing slow speeds or no connectivity at all. Incorrect IP configurations, faulty firmware updates, or improper network protocols can all be culprits. Regular software audits and updates are essential to keep everything running smoothly.

9. Electromagnetic Interference

Although fiber optics are less prone to electromagnetic interference than copper cables, the equipment connected to them is not. Servers, switches, and other network devices can be affected by strong electromagnetic fields, leading to data corruption or loss. Proper shielding and physical separation from known sources of interference can mitigate these risks.

10. Environmental Factors

When fiber cables get too hot, too wet, or come into contact with harsh chemicals, trouble starts. Heat can make the cables lose shape, moisture can weaken the fibers inside, and chemicals can eat away the protective outer layer. To keep cables safe, use the right kind of protection like tough jackets that keep out water and chemicals.

Best Practices for Fiber Optics Cable

To ensure your fiber optic cables function at their best, follow these guidelines from start to finish.

Conduct a Site Survey

Before laying a single cable, scope out your site. You’re looking for any tricky spots like areas with high heat or too close to power lines. Also, brush up on local building codes to avoid surprises. This step is all about dodging future headaches by planning the best path for your cables.

Watch the Load

Fiber cables might be tough, but they have their limits. Don’t exceed the maximum pull force to avoid damage. It’s a simple rule that keeps your cables intact and functional.

Plan the Cable Pull

Use your site survey findings to plan your cable pull. This includes figuring out the path, equipment needed, and deciding who’s doing what. A solid plan here means a smoother installation with fewer hiccups.

Label Your Cables

A well-labeled system is a joy to work with. It makes maintenance, upgrades, and troubleshooting way easier. Plus, it keeps things safe and organized.

Cover and Protect

Keep those cable ends covered to block out moisture. Leaving reels unattended or not protecting the ends can lead to moisture damage, which is a no-go for fiber optics.

Handle With Care

Fiber optic cables are not your average cables. They need a gentle touch, so no pinching, twisting, or bending too sharply. Treat them right to keep them transmitting data smoothly.

Cleanliness is Key

A dirty cable can wreak havoc on your network. Keep things clean for a strong, reliable connection. This means using the right tools and techniques every time.

Manage Cables Smartly

A neat network is a happy network. Use both horizontal and vertical management to keep cables orderly. It makes future changes and troubleshooting much simpler.

Invest in Structured Cabling

Structured cabling installation is the way to go for a robust and flexible network. It organizes your cabling system efficiently, making it easier to manage and upgrade. Planning this from the outset sets you up for success.

Conclusion

Issues with fiber cables are common. But by following the recommended steps—careful planning, accurate installation, and regular maintenance—your company can sidestep these hurdles. Stay connected, not entangled, in your pursuit of network excellence.

Video

Infographic

Fiber optic cabling improves integration and efficiency but can be costly when it fails. Identifying and mitigating common failures is essential for smooth operations. Explore our infographic for issues and prevention strategies.